In the ongoing quest for sustainable agricultural practices and waste management solutions, small-scale biochar production has emerged as a compelling alternative. The process, which involves converting biomass into charcoal via pyrolysis, not only sequesters carbon but also enhances soil health. However, the efficacy of this transformative practice heavily relies on the design of the biochar kiln employed. This article delves into various kiln designs, contemplating their unique features, advantages, and potential shortcomings. By illuminating these distinctions, readers can better understand which small-scale biochar kiln design may be most suitable for their needs.

Understanding Biochar and Its Benefits

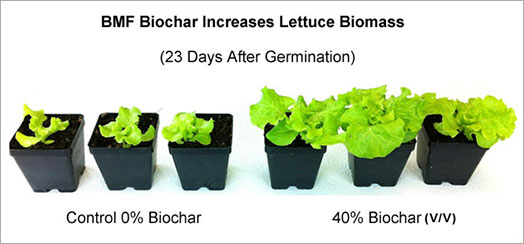

Before exploring the myriad of kiln designs, it’s essential to grasp the nuances of biochar itself. Biochar is not merely a byproduct of organic waste; it’s a carbon-rich material that possesses remarkable properties. As a soil amendment, it can improve nutrient retention, promote microbial health, and even mitigate climate change by sequestering carbon for extended periods. Furthermore, its porous structure enables it to retain moisture, making it invaluable in drought-stricken areas.

Simple Pit Kilns: The Primitive Yet Effective Solution

Pit kilns, often lauded as the most rudimentary design, utilize basic excavation techniques to create a simple pit where biomass is placed and ignited. This method comes with a distinct advantage: low cost. The setup requires minimal resources and can be executed with local materials. However, challenges arise with inconsistent heat distribution, often resulting in uneven char quality.

Despite these drawbacks, many smallholder farmers find pit kilns advantageous for their straightforward operation. This simple design fosters a rudimentary yet effective introduction to biochar production, allowing novices to engage with sustainable practices without overwhelming financial commitments.

Drum Kilns: A Step Up in Efficiency

Transitioning from the primitive pit kiln, drum kilns present a more refined option. Typically constructed from repurposed oil drums, these kilns bring several critical improvements to the table. Enhanced temperature control is a notable advantage; the closed design traps heat more effectively than an open pit, promoting a more consistent pyrolytic process.

These kilns employ a top-lit updraft method, allowing for efficient combustion. As a result, operators can achieve good yield of high-quality biochar. Furthermore, when outfitted with a chimney, drum kilns can reduce emissions significantly, aligning closely with environmental regulations. Yet, they still leave room for innovation for those who desire further efficiency.

TLUD Kilns: The Genius of Top-Lit Updraft

The Top-Lit Updraft (TLUD) kiln stands as a testament to the ingenuity of biochar technology. This design embraces a two-stage pyrolysis process that greatly improves efficiency and biochar quality. In essence, the fuel is ignited from the top, and as the fire moves downward, it creates a vacuum that pulls in air, achieving a more uniform burn.

The TLUD’s design allows for the production of biochar while simultaneously using the volatile gases released during pyrolysis for cooking or heating. This dual-purpose functionality embodies the ideals of resourcefulness and sustainability. Although more complex than pit or drum designs, those who invest in understanding and operating a TLUD kiln may find the benefits far outweigh the initial learning curve.

Continuous Feed Kilns: Advanced Efficiency for Larger Operations

As the scale of production increases, the need for efficiency and output becomes more pronounced. Continuous feed kilns cater to this demand, allowing users to introduce biomass continuously while producing biochar consistently. With a design that optimally utilizes space, these kilns can yield large quantities of biochar while minimizing labor input.

However, the initial investment and maintenance costs can deter small-scale producers. Moreover, these kilns require a higher level of technical knowledge and an understanding of thermal dynamics to operate effectively. Despite these challenges, for those seeking a more commercial-level output, continuous feed kilns could be the answer.

Comparison of Designs: Evaluating Pros and Cons

When selecting the ideal small-scale biochar kiln, one must weigh not only the design features but also the specific needs and resources at hand. Pit kilns shine in terms of simplicity and accessibility, ideal for those just starting their journey into biochar. In contrast, drum and TLUD kilns offer increased efficiency and higher-quality outputs, albeit with a steeper learning curve. Continuous feed kilns, while potentially rewarding in terms of output, necessitate a significant investment and technical acumen.

Furthermore, the regional context plays a critical role. Local biomass availability, financial resources, and intended applications of biochar significantly influence the decision-making process. For example, smallholder farmers in remote areas may favor pit kilns due to their low cost and minimal construction requirements, while larger agricultural operations could benefit from investing in more advanced designs.

The Future of Small-Scale Biochar Production

As global awareness around climate change and sustainability grows, the demand for innovative solutions continues to rise. Small-scale biochar production not only contributes to this need but also empowers communities to engage actively in ecological restoration. The advancements in kiln designs reflect the ongoing quest for efficiency, sustainability, and practicality in agricultural practices.

In conclusion, the exploration of small-scale biochar kilns unveils a captivating array of choices, each with inherent strengths and weaknesses. The optimal design depends on various factors, including the user’s objectives, available resources, and environmental context. With persuasive evidence supporting the benefits of biochar, delving into these designs can be the first step toward embarking on a sustainable and productive agricultural journey.