When it comes to eco-friendly solutions for soil enrichment and waste management, biochar has emerged as a phenomenon worth exploring. Yet, for enthusiasts and agriculturists looking to produce their own biochar, the implementation often boils down to one pivotal question: should you invest in a stainless steel portable biochar kiln? This article delves into the features and field performance of these kilns, highlighting both the advantages and the challenges they present.

Understanding Biochar: A Brief Overview

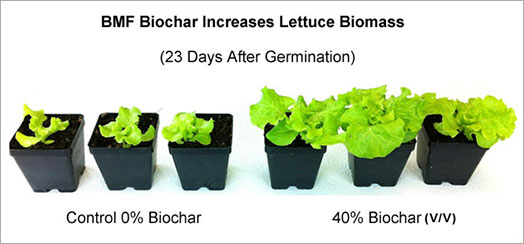

Biochar is a carbon-rich product derived from the pyrolysis of organic materials such as wood, crop residues, and even animal manures. The process involves heating biomass in a low-oxygen environment, which minimizes the release of gases and effectively sequesters carbon. The resultant biochar serves myriad purposes: it enhances soil fertility, improves water retention, and can even mitigate greenhouse gas emissions. Thus, possessing a portable kiln for biochar production could be a game-changer.

What Makes Stainless Steel Kilns Unique?

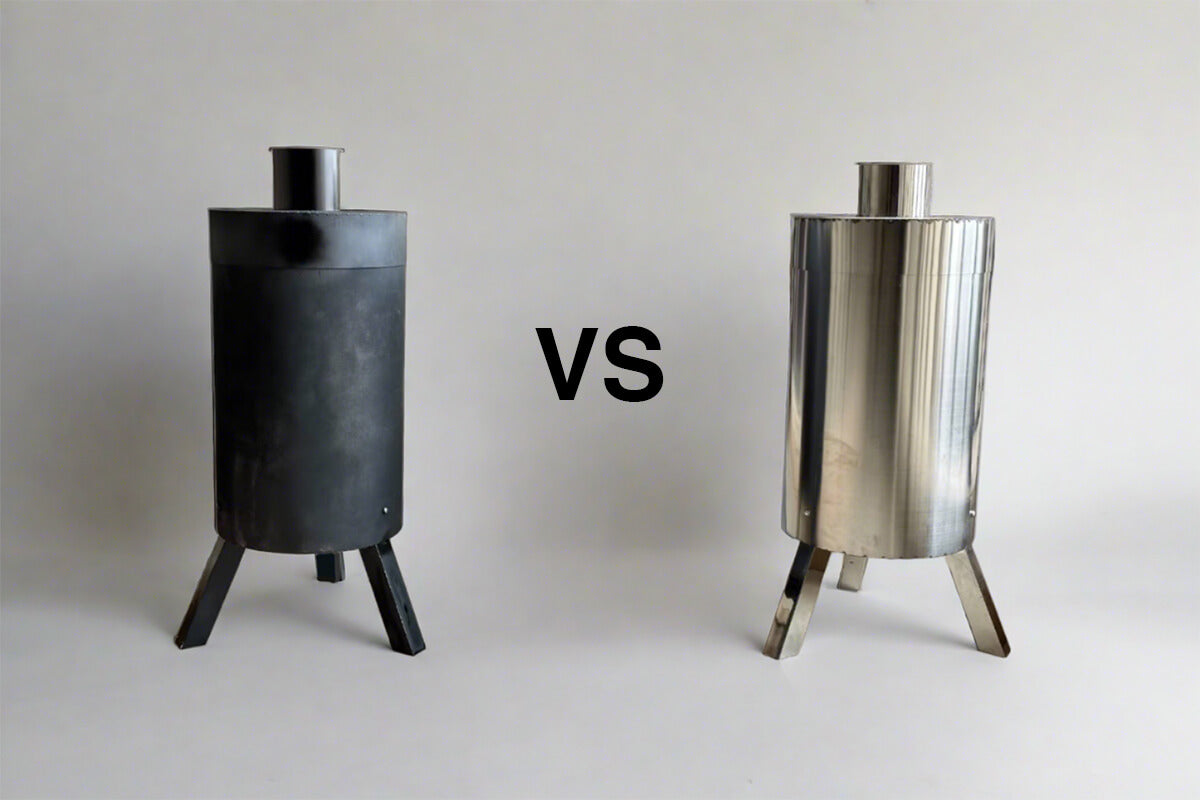

Steel is known for its durability, and when it comes to biochar production, the choice between cold-rolled steel and stainless steel is particularly significant. Stainless steel kilns bring a host of exceptional properties to the table:

- Corrosion Resistance: Unlike cold-rolled steel, which is susceptible to rust and degradation over time, stainless steel offers remarkable resistance to corrosion. This essential characteristic ensures longevity even in diverse climatic conditions, making it a go-to choice for outdoor applications.

- Heat Retention: Stainless steel has superior heat retention qualities. This property is crucial for optimizing pyrolysis temperatures and improving overall efficiency. By maintaining consistent thermal conditions, these kilns can yield high-grade biochar with enhanced properties.

- Lightweight and Portable: Many portable kilns made of stainless steel are designed to be lightweight, which enhances mobility. This feature allows users to transport the kiln easily across different sites and makes it practical for farms, gardens, or even camping trips.

Field Performance: Efficiency Meets Usability

In real-world scenarios, the performance of stainless steel portable biochar kilns has proven to be commendable. Users have reported varied experiences depending on the scale and type of biomass used. Nevertheless, several common themes regarding efficiency and usability emerge:

- Speed of Biochar Production: Due to enhanced heat retention and effective insulation, stainless steel kilns often reduce the time taken to produce biochar. Some users note production cycles that can last anywhere from two to six hours, a substantial improvement over traditional methods that could take days.

- Versatile Biomass Feedstock: Another remarkable aspect of these kilns is their ability to handle diverse feedstock. Whether it’s agricultural residues or urban wood waste, stainless steel kilns can accommodate a broad spectrum of materials, ultimately broadening the range of potential users.

- Ease of Operation: Designed with user experience in mind, many stainless steel kilns feature intuitive controls for temperature and airflow management. This user-friendliness invites even novices to delve into biochar production without feeling overwhelmed.

But are there limitations?

While stellar performance is a hallmark of stainless steel kilns, certain challenges demand attention. One potential issue is the initial financial investment. Stainless steel is inherently more expensive than its cold-rolled counterpart, leading to a higher upfront cost. Can one justify this investment in terms of longevity and efficiency? The answer varies based on individual needs and usage frequency. Additionally, the size of the kiln can restrict the volume of biochar produced at one time. If you envision large-scale biochar production, a smaller portable unit may not suffice, requiring foresight into future production needs.

Best Practices for Utilizing Stainless Steel Biochar Kilns

To maximize the potential of a stainless steel portable biochar kiln, users should adhere to several best practices:

- Pre-Processing Biomass: Ensuring your feedstock is appropriately sized will enhance the pyrolysis process. Chopping or shredding materials can improve airflow and promote even heating.

- Temperature Monitoring: Maintaining optimal pyrolysis temperatures is imperative for producing high-quality biochar. Utilizing thermometers or digital sensors can assist in monitoring heat levels.

- Safety Considerations: Operating with fire brings inherent risks. Always observe safety protocols, including using protective gear and keeping fire extinguishing resources nearby.

Conclusion: A Sustainable Investment?

In summary, stainless steel portable biochar kilns offer a fusion of durability, efficiency, and usability that make them an attractive option for both hobbyists and serious producers. While they do pose certain challenges, particularly in terms of initial costs and production capacity, their overall benefits—including longevity and superior biochar production—might just outweigh those concerns. As you ponder the essentials of biochar production, consider whether this investment aligns with your sustainable practices. Isn’t it time to elevate your environmental impact while enhancing your soil health?