In recent years, the eco-conscious movement has gained considerable momentum, with tire recycling emerging as a key component of sustainability efforts. Tire pyrolysis, in particular, has piqued curiosity. This innovative process converts end-of-life tires into valuable byproducts, such as oil, carbon black, and gas, while minimizing environmental impact. But are there successful tire pyrolysis plants in America? This exploration delves into the truth behind tire pyrolysis operations across the United States, showcasing their benefits, challenges, and the landscape of the industry.

The Pyrolysis Process Explained

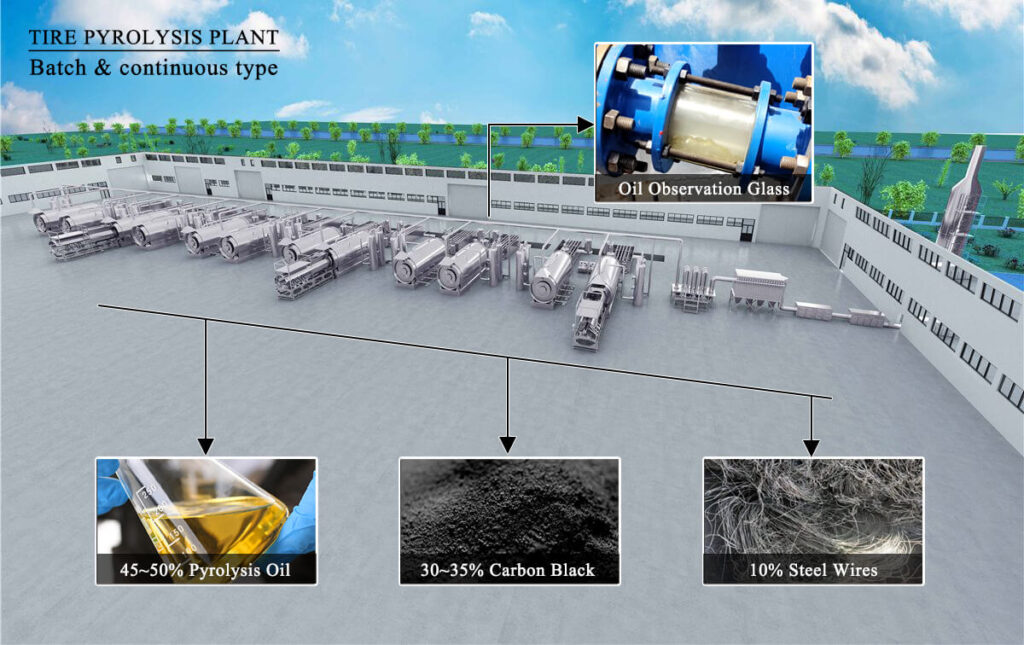

Tire pyrolysis is a thermal decomposition process that occurs in the absence of oxygen. By subjecting tires to high temperatures (typically between 400°C to 600°C), the organic materials within them break down into useful products. These products include:

- Pyrolysis Oil: This oil can be refined into diesel-like fuel or further processed into various chemicals.

- Carbon Black: The solid residue left behind can be utilized in the manufacturing of new tires or as a pigment in various industries.

- Gaseous Fuels: Gases collected during pyrolysis can be recycled to provide energy for the process itself, making it more efficient.

This versatile methodology appears promising, particularly in addressing the ubiquitous problem of scrap tire disposal. Each year, the United States generates approximately 290 million scrap tires, representing a significant environmental challenge. However, the crucial question remains: how successful are these pyrolysis plants?

Success Stories Across the Nation

While challenges exist, several tire pyrolysis facilities in the U.S. have experienced notable successes, paving the way for broader implementation. Noteworthy examples include:

- Green Tire Recycling: Located in Los Angeles, California, Green Tire Recycling operates a state-of-the-art tire pyrolysis plant that converts used tires into fuel oil and carbon black. Their innovative approach has garnered investments and partnerships with local governments keen on improving waste management.

- Liberty Tire Recycling: As one of the leading processors of scrap tires in the U.S., Liberty Tire Recycling has launched pilot pyrolysis projects. Although they primarily focus on retreading and shredding, their foray into pyrolysis presents promising avenues to enhance their operations and sustainability profile.

- Pyrolyx AG: This multinational company has established a presence in the U.S., operating a facility in Terre Haute, Indiana. Pyrolyx uses advanced technology to produce high-quality carbon black from scrap tires, demonstrating the economic viability of the pyrolysis process on American soil.

Economic Viability and Environmental Impact

The financial feasibility of tire pyrolysis remains a critical component of its success. Many plants combine the sale of products with government incentives aimed at reducing waste. These incentives, which vary by state, play an instrumental role in promoting the establishment of pyrolysis facilities.

Moreover, the environmental ramifications are significant. Tire pyrolysis can effectively mitigate pollution. By diverting tires from landfills—where they can release harmful toxins and contribute to environmental degradation—pyrolysis offers a sustainable solution. Additionally, the end products have valuable applications, which enhances the economic incentive.

However, the environmental benefits hinge on efficient operation. Plants must incorporate technologies to minimize emissions during the pyrolysis process, which can be challenging. This aspect has been a focal point for regulatory bodies assessing plant applications and operational permits.

Challenges Faced by Pyrolysis Plants

- Regulatory Hurdles: Each state has its own set of environmental regulations that can complicate the establishment and operation of pyrolysis facilities. Navigating these regulatory frameworks requires diligence and persistence.

- Capital Investment: The initial outlay for building pyrolysis plants can be exorbitant, deterring potential investors. Securing funding remains a perennial challenge for entrepreneurs venturing into this industry.

- Market Demand Variability: The demand for byproducts such as pyrolysis oil and carbon black can fluctuate based on global market conditions. Ensuring a steady market for these products is essential for long-term success.

The Future of Tire Pyrolysis in America

The future of tire pyrolysis in America appears promising, albeit fraught with challenges. As the environmental imperatives become more pressing, and as technological advancements continue to emerge, the potential for success grows. Investment in research and development can enhance the efficiency and economic viability of these plants, leading to a ripple effect across the nation.

Furthermore, public awareness and demand for sustainable practices are expanding. As consumers and communities advocate for eco-friendly solutions, tire pyrolysis is likely to receive greater support at various levels. This cultural shift toward sustainability may prompt more investors to consider tire pyrolysis as a viable business endeavor.

Conclusion

In summary, successful tire pyrolysis plants exist in America, supporting the dual objectives of waste reduction and resource recovery. While challenges such as regulatory frameworks, capital investments, and market demand remain, the potential rewards—both economic and environmental—are substantial. As the industry evolves, one can hope for a future where tire pyrolysis becomes a staple in sustainable waste management practices across the nation.