Biochar Pyrolysis Equipment: What You Need to Know Before Buying

As environmental concerns continue to grow, an intriguing question emerges in the world of sustainable practices: how can we harness the power of biomass to enrich our soils while also sequestering carbon? Enter biochar—a charcoal-like substance that has gained considerable attention for its agricultural benefits and its role in carbon sequestration. But hold on! Before you leap into the world of biochar production, it’s essential to understand the equipment involved, namely biochar pyrolysis equipment. Purchasing the right apparatus can feel like finding a needle in a haystack, so let’s dissect the intricacies of biochar pyrolysis equipment and what you need to know before making that investment.

Understanding Biochar and Pyrolysis

Before navigating the realm of equipment, it’s paramount to understand what biochar is and how it is produced. Biochar is created through a process known as pyrolysis, where organic material—such as wood chips, agricultural residues, or even manure—is heated in the absence of oxygen. This thermal decomposition results in the conversion of the biomass into charcoal, along with the production of combustible gases and bio-oil.

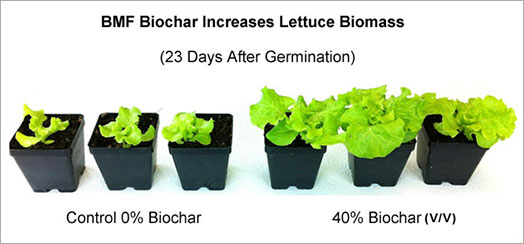

The resulting biochar is not only a potent soil amendment but is also instrumental in capturing carbon dioxide from the atmosphere, making it a formidable player against climate change. However, the benefits of biochar are directly affected by the pyrolysis technology used, necessitating careful consideration when selecting equipment.

Types of Biochar Pyrolysis Equipment

Upon deciding to venture into biochar production, you will discover various types of pyrolysis equipment available in the market. Each type varies in complexity, efficiency, and capacity. Here are the general categories:

- Batch Reactors: These compact systems are typically suitable for small-scale production. The biomass is loaded, pyrolyzed, and then removed in a batch operation. While they are more affordable, they may be less efficient and restrict continuous operation.

- Continuous Reactors: This equipment allows for a continuous feed of biomass. Though more expensive, continuous reactors facilitate higher volumes of biochar production and generally yield better efficiency in heat recovery.

- Gasifiers: These systems convert biomass into synthesis gas, which can then be used to generate electricity or produce biochar. They involve higher complexity but provide versatility in output.

Choosing the right type of equipment will largely depend on your production goals, budget, and environmental considerations. Are you looking for a small-scale project or something capable of industrial production?

Key Features to Consider

Beyond the type, there are specific features you must consider before purchasing biochar pyrolysis equipment:

- Temperature Control: Pyrolysis requires precise temperature control to achieve optimal char quality. Look for equipment that offers reliable temperature monitoring and regulation.

- Feedstock Capacity: Assess your expected feedstock availability. Equipment with larger feedstock capacity may be more suitable for those anticipating bulk biomass processing.

- Thermal Efficiency: The rate at which the equipment can convert biomass into biochar is crucial. Higher thermal efficiency not only saves energy but also improves economic viability.

- Emissions Control: Environmental regulations necessitate safe emissions. Ensure that the equipment has adequate emission control mechanisms to minimize environmental impact.

- Durability and Maintenance: Since pyrolysis equipment operates under high temperatures, durability becomes essential. Research the materials used in manufacturing and assess the maintenance requirements.

Costs and Budgeting

It is also wise to consider ancillary costs, including installation, transportation, and ongoing maintenance. Is your budget flexible enough to accommodate these potential expenses, or are you approaching a hard limit?

Space Considerations

When selecting biochar pyrolysis equipment, one cannot overlook the spatial requirements. Larger systems may demand substantial real estate, particularly if they are part of an industrial setup. Conduct an evaluation of your intended site to ensure there is adequate space for machinery and the necessary safety protocols are in place. Furthermore, consider the proximity to feedstock sources and your market for biochar.

Supplier Reputation and Support

Conclusion

In conclusion, investing in biochar pyrolysis equipment can be a transformative step towards achieving sustainable agricultural practices and contributing to climate mitigation efforts. With an array of equipment types, features, and considerations at your disposal, conducting thorough research and evaluating your specific needs is imperative before making a purchase. As you ponder your options, ask yourself—will your venture be an eco-friendly triumph or an unexpected conundrum? The choice is yours!