Biochar, a carbon-rich byproduct derived from the pyrolysis of biomass, has gained significant traction in recent years due to its multifaceted applications and environmental benefits. Integral to the production of biochar are industrial reactors, which facilitate the transformation of organic materials into this valuable substance. As we delve into the world of biochar and industrial reactors, we will explore their mechanisms, types, benefits, and applications, providing a comprehensive understanding of this innovative process.

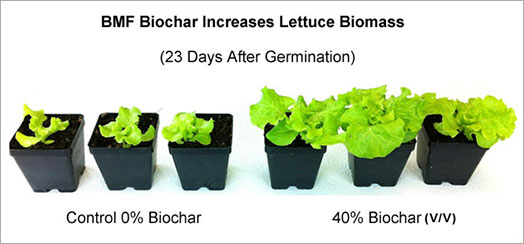

At its core, biochar production involves pyrolysis, a thermochemical decomposition process that occurs in the absence of oxygen. This procedure allows biomass—such as agricultural residues, forestry waste, and even some types of municipal solid waste—to be converted into a stable form of carbon. The biochar produced not only sequesters carbon but also enhances soil fertility and water retention, thus improving crop yield—a pivotal advantage in addressing climate change and food security.

Industrial reactors play a vital role in this transformation. They create the necessary high-temperature environment and replicate the conditions needed for efficient biomass conversion. Various types of reactors are employed in biochar production, each with unique characteristics and suitability for different biomass feedstocks.

One of the most prevalent types of industrial reactors is the fixed bed reactor. This design involves packing biomass in a vertical column, allowing for efficient heat transfer and gas flow. The fixed bed reactor is known for its simplicity and cost-effectiveness, making it a popular choice for small to medium-sized operations. However, its limitations include uneven heating and the risk of clogging, which can hamper production efficiency.

In contrast, the fluidized bed reactor offers improved heat transfer and biomass residence time. In this system, solid particles are suspended in a stream of gas or liquid, creating a fluid-like state. This enhances mixing and uniform heating, thereby promoting more consistent biochar quality. Although fluidized bed reactors typically require more complex mechanical designs and are costlier, they are particularly effective for a broader variety of feedstocks.

Another notable reactor type is the rotary kiln reactor, an apparatus in which biomass is subjected to intense heat as it moves through a rotating cylinder. This continuous flow reactor maximizes thermal efficiency and is particularly adept at handling larger volumes of biomass. The rotary kiln’s ability to maintain high temperatures for extended periods helps achieve complete biomass conversion, resulting in high-quality biochar. However, the energy requirements and substantial capital investment can pose challenges for some producers.

Lastly, the bubbling fluidized bed reactor represents an innovative hybrid approach. This design utilizes bubbles of gas to circulate solid biomass within a heated chamber. Such a configuration allows for exceptionally efficient heat transfer and chemical reactions, optimizing the conversion process. As research into this technology advances, it may bridge many of the gaps found in traditional reactor designs, presenting an exciting avenue for industrial biochar production.

The choice of reactor directly impacts not only the efficiency of biochar production but also its characteristics. For instance, temperature control, residence time, and feedstock type all influence the final product’s physical and chemical properties. Variations in these parameters can produce biochar with tailored functionalities—important for specific applications in agriculture, soil remediation, and carbon sequestration.

Beyond their mechanical intricacies, industrial reactors for biochar production hold profound implications for sustainability and environmental stewardship. Given their role in reducing greenhouse gas emissions through carbon sequestering, they are particularly relevant in the context of climate change mitigation strategies. By converting biomass waste into biochar, we can lessen landfill dependence while simultaneously enriching soil health.

One of the remarkable benefits of biochar produced in industrial reactors pertains to its role as a soil amendment. Biochar improves soil structure, aeration, and water retention, enabling crops to thrive even in arid conditions. Additionally, its porous nature allows for the adsorption of nutrients and pollutants, making it effective for remediating contaminated soils. Farmers and agronomists are increasingly recognizing the potential of biochar to enhance agricultural productivity while minimizing the reliance on chemical fertilizers.

Moreover, biochar’s ability to demonstrate strong adsorption properties is being investigated for applications in wastewater treatment and air purification. It serves as a filtering agent, absorbing harmful molecules and heavy metals, ultimately contributing to cleaner water bodies and improved air quality. The versatility of biochar augments the traditional views of biomass as a waste material, placing it at the forefront of sustainable innovation.

On the economic front, the establishment of biochar production facilities using industrial reactors can stimulate local economies. These facilities create jobs, reduce waste management costs, and generate value through the sale of biochar products. As awareness of the benefits of biochar grows, so too does its market potential—making it an appealing opportunity for entrepreneurs and investors alike.

In conclusion, biochar production through industrial reactors stands at the confluence of innovation and sustainability. With various reactor types, each offering unique advantages and challenges, the field continues to evolve. As society embraces the imperatives of environmental stewardship and sustainable agriculture, the multifaceted applications of biochar cement its role as an essential element in creating a greener, more sustainable future. The journey for biochar—from biomass to a transformational soil amendment and carbon sink—illustrates the profound possibilities emerging from the intersection of technology and environmental consciousness.