Imagine a world where agricultural waste transforms into a valuable resource, reducing pollution while enriching the soil. What if every piece of sugarcane waste could be turned into biochar, a powerhouse for carbon sequestration? This captivating metamorphosis occurs in pyrolysis plants, where the humble remnants of sugarcane are reborn as biochar. Today, we delve into the compelling narrative of making biochar from sugarcane waste, elucidating the role of pyrolysis plants in this sustainable enterprise.

To comprehend the magnitude of this endeavor, one must first grasp the essence of sugarcane waste. After the sugar extraction process, farmers are often left with vast quantities of bagasse, leaves, and other fibrous materials. Historically deemed as agricultural debris, these waste products have been underutilized. Yet, through the innovative process of pyrolysis, they can be converted into biochar, thereby addressing two pressing environmental challenges: waste management and climate change.

Pyrolysis is an intricate thermal decomposition process conducted in the absence of oxygen. By heating sugarcane waste to high temperatures—typically between 300 to 700 degrees Celsius—the plant material undergoes a transformation, yielding biochar, bio-oil, and syngas. This multifaceted output enhances the economic viability of biomass waste treatment. But how exactly does it work?

As the sugarcane waste is fed into the pyrolysis reactor, it encounters progressively rising temperatures. Initially, moisture evaporates, followed by the breakdown of cellulose and hemicellulose. This phase generates gaseous byproducts, which can be captured and utilized for energy production. The subsequent temperature elevation leads to the carbonization of the remaining solid material, resulting in the creation of robust biochar. The entire process is carefully monitored to maximize output while minimizing emissions, ensuring adherence to environmental regulations.

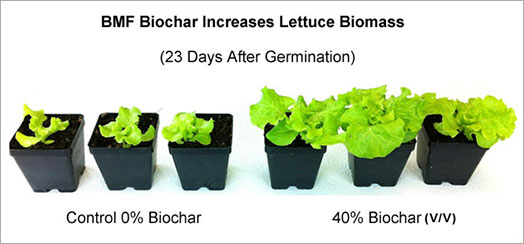

The implications of such technology are profound. In regions where sugarcane is a primary crop, pyrolysis plants present an eco-friendly solution to waste disposal. Farmers can take advantage of a circular economy by converting what was once waste into a profitable product. Additionally, biochar holds exceptional properties as a soil amendment. When incorporated into agricultural lands, it enhances soil structure, improves water retention, and boosts nutrient availability. This could potentially lead to increased agricultural productivity—something every farmer dreams of.

However, the journey from sugarcane waste to biochar is not devoid of challenges. One must consider the operational and technical hurdles faced by pyrolysis plants. The initial investment required for establishing these facilities can be substantial, posing a barrier to widespread adoption. Furthermore, ensuring consistent feedstock supply is integral for the plant’s efficiency. Fluctuating farming practices or seasonal variations can hinder this availability, complicating the operational dynamics of pyrolysis plants.

Moreover, the quality of biochar produced is heavily influenced by the process parameters. Factors such as temperature, heating rate, and residence time play critical roles in determining the final product’s qualities. Does the pursuit of optimal conditions warrant additional complexity? Indeed, optimizing these parameters calls for ongoing research and development efforts, pushing the boundaries of current technological capabilities.

Despite these challenges, the positive ramifications of utilizing pyrolysis plants for biochar production are too significant to ignore. The integration of these facilities into agricultural ecosystems fosters innovation in waste management. By minimizing the environmental footprint associated with burning or landfilling sugarcane waste, these plants contribute to cleaner air and soil. Additionally, as the world increasingly grapples with the implications of climate change, strategies for carbon sequestration become paramount. Biochar, with its stable carbon content, emerges as a strong contender in sequestering carbon and mitigating greenhouse gas emissions.

As we peer into the future, the role of pyrolysis in biomaterials appears promising. The potential for research advancements may unveil new processes capable of enhancing biochar production efficiency and quality. Furthermore, policymakers are beginning to recognize the health and environmental benefits associated with biochar, paving the way for supportive legislation and funding opportunities. This could potentially accelerate the construction of pyrolysis plants, thereby solidifying their place as linchpins in sustainable agricultural practices.

In conclusion, the story of making biochar from sugarcane waste is a brilliant testament to human ingenuity and nature’s resilience. While challenges persist, the collaborative efforts of agronomists, engineers, and environmentalists can unlock the intricacies of pyrolysis technology. Imagine a future where every sugarcane farm doubles as a biochar production unit, enhancing soil health while addressing global environmental issues. This is not just a dream—it’s a possibility within our reach, waiting for us to grasp it.