In the ever-evolving discourse surrounding sustainable agriculture and environmental stewardship, biochar emerges as a captivating subject, entwining ancient practices with modern technology. Its potential to revolutionize soil health and mitigate climate change is garnering attention from farmers and environmentalists alike. Central to the production of this remarkable carbon-rich substance is the Standard Air Burners FireBox, a tool that simplifies the biochar-making process while promising efficacy and sustainability.

This field guide serves as a beacon for those curious minds eager to embark on the journey of biochar production. Understanding the nuances of this process can unveil a wealth of opportunities for soil amelioration and carbon management, beckoning individuals to shift their perspectives on organic waste and its integral role in environmental remediation.

The Essence of Biochar

At its core, biochar is a form of charcoal that is produced through pyrolysis — the thermal decomposition of organic material in the absence of oxygen. This ancient technique, once reserved for traditional farming cultures, has resurfaced as a pivotal strategy in modern sustainable practices. Why is biochar garnering such acclaim? First, its porous structure enhances soil aeration and water retention, while the carbon-rich matrix provides a habitat for beneficial microorganisms. Moreover, biochar is a fantastic carbon sink, sequestering carbon dioxide that would otherwise contribute to atmospheric pollution.

The confluence of these properties enables biochar to enhance soil fertility while concurrently addressing the pressing challenges of climate change. By producing biochar responsibly and efficiently with the Standard Air Burners FireBox, individuals are not merely participating in a practice; they are contributing to a larger narrative of ecological harmony.

The Standard Air Burners FireBox: An Overview

The Standard Air Burners FireBox stands out as an innovative, efficient, and environmentally conscious solution for creating biochar. This external furnace is designed to facilitate the controlled combustion of biomass, transforming wood wastes, debris, and other organic matter into biochar with minimal emissions. With an emphasis on operational efficiency, the FireBox employs a dual-burn system that reduces smoke output, effectively addressing air quality concerns commonly associated with traditional burning methods.

Preparing for Biochar Production

Before embarking on the biochar-making endeavor, adequate preparation is paramount. Start by collecting the appropriate biomass feedstock; this can include wood chips, agricultural residues, and even certain types of yard waste. The key is to ensure the material is dry and free from contaminants, as moisture and toxins can compromise the quality of the produced biochar.

Next, familiarize yourself with the FireBox operations manual; understanding the intricacies of this machine is essential for ensuring safety and efficacy. Pay close attention to the setup procedures, as proper installation and maintenance of the FireBox will facilitate a smoother biochar production experience.

The Process of Making Biochar

Once you have your biomass prepared and the FireBox configured, the biochar production process can begin. Start by loading the biomass into the designated chamber. The FireBox’s unique design encourages optimal airflow, thus promoting efficient combustion.

Choose your temperature settings wisely. Biochar quality largely depends on the pyrolysis temperature; typically, a range of 300°C to 700°C is optimal. Lower temperatures yield biochar that is rich in nutrients, while higher temperatures can produce char with enhanced structural features. Monitor the process with vigilant attention, making adjustments as necessary to maintain steady combustion.

Through the combustion cycle, the biomass transitions through distinct phases; it will ignite, smolder, and eventually convert to biochar. This transformation may take several hours. However, the results are genuinely worth the wait—an organic substance that carries the potential to reinvigorate degraded soils and improve agricultural productivity.

Transforming Your Garden and Farm

Once the biochar is created, cooling it down is vital before handling. Once cooled, the biochar can be crushed or ground into finer particles, making it easier to integrate into your soil. Incorporate biochar into existing soil systems at a rate of 5-10% to reap its full benefits.

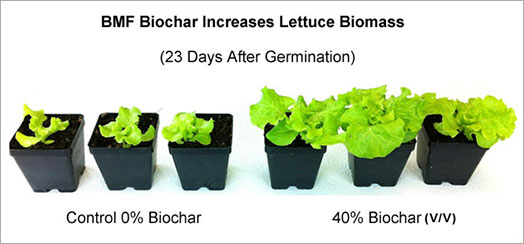

The integration of biochar enriches the soil microbiome, enhances nutrient-use efficiency, and boosts the availability of water. Whether it is through garden beds, orchard plots, or crop fields, the application of biochar catalyzes a transformative effect. While many may perceive this process as labor-intensive, the long-term benefits yield an impressive return on investment in terms of soil vitality and crop yield.

Regenerating the Environment

Beyond agricultural enhancements, the practice of making biochar with a Standard Air Burners FireBox champions environmental regeneration. The strategic conversion of waste biomass into biochar curtails landfill contributions, lowering methane emissions during waste decay. Moreover, as a carbon-negative strategy, biochar production actively contributes to mitigating climate change by sequestering carbon emissions.

Yet, the benefits extend further — biochar acts as a natural filter for pollutants, reducing leaching into local waterways and enhancing overall ecosystem health. As practitioners harness this tool, they become stewards of the land, leading the charge towards a more sustainable future.

Conclusion

In conclusion, the Standard Air Burners FireBox serves as an essential conduit for those eager to unlock the many wonders of biochar. This field guide highlights a multifaceted approach, bridging ancient knowledge with contemporary environmental challenges. As innovators in the agricultural sphere, embracing biochar not only enriches soil health but facilitates a deeper connection with the land. With each batch produced, practitioners contribute to a sustainable framework, embodying a promising shift towards ecological balance and regeneration.