Small-scale biochar production is an innovative approach that resonates with those who are keen to enhance soil fertility, sequester carbon, and promote sustainable agricultural practices. The allure of creating biochar lies in its multifaceted benefits, coupled with a profound sense of accomplishment that comes from transforming organic waste into a resource that can rejuvenate soils and significantly mitigate environmental impact. This step-by-step guide will delve into the nuances of producing biochar on a small scale, exploring various methods, materials, equipment, and the broader implications of this carbon-rich soil amendment.

1. Understanding Biochar: The Basics

Biochar is a form of charcoal produced through pyrolysis, a process that involves heating organic material in the absence of oxygen. The resultant biochar retains a complex structure that not only enhances soil health but also aids in carbon sequestration. The fascination with biochar isn’t merely academic; farmers, gardeners, and environmentalists alike are captivated by its potential to revolutionize agricultural practices as we know them.

2. The Rationale Behind Small-Scale Production

Engaging in small-scale biochar production offers numerous advantages over larger operations. Firstly, it allows individuals and communities to directly manage their organic waste, thus promoting local sustainability. Furthermore, small-scale systems are often more affordable and accessible, enabling more people to partake in this eco-friendly endeavor. The deep-seated reasons for gravitating toward small-scale biochar production stem from a desire for self-sufficiency, ecological stewardship, and the intrinsic satisfaction of utilizing waste to create a beneficial product.

3. Materials Required for Production

To embark on your journey of biochar production, several materials are essential:

- Feedstock: The organic materials you choose will significantly affect the quality of your biochar. Common options include wood chips, straw, agricultural residues, and even animal manure. Each feedstock imparts unique characteristics to the final product.

- Equipment: There are a variety of small-scale pyrolysis units available on the market, ranging from simple drum kilns to advanced retort systems. Selecting the right apparatus will depend on your budget, production goals, and the quantity of feedstock available.

- Safety Gear: It is essential to prioritize safety when working with equipment that produces high temperatures and smoke. Necessary gear includes gloves, goggles, and a mask to mitigate exposure to any potentially harmful emissions.

4. Step-by-Step Process

Once you have gathered your materials, the following steps outline the biochar production process:

Step 1: Choose Your Feedstock

Select an appropriate feedstock based on availability and your specific objectives. Ideally, the feedstock should be dry and chopped into small pieces to facilitate efficient pyrolysis.

Step 2: Preparing the Pyrolysis Unit

Depending on your chosen equipment, set up your pyrolysis unit according to the manufacturer’s instructions. Ensure that the unit is situated away from flammable materials and in a well-ventilated area.

Step 3: Loading the Feedstock

Carefully load the prepared feedstock into the pyrolysis unit, ensuring that it is packed loosely enough to allow airflow while maintaining the appropriate density for effective charring.

Step 4: Initiating Pyrolysis

Ignite the feedstock and monitor the temperature. The process generally requires maintaining a temperature between 400°F and 800°F. As the feedstock heats, it will begin to transform into biochar, releasing volatile gases.

Step 5: Cooling and Collecting Biochar

Once pyrolysis is complete, allow the unit to cool down fully before proceeding to extract the biochar. This cooling process can take several hours. Once cooled, carefully remove the biochar and make sure to store it in an airtight container to preserve its benefits.

5. Post-Production Considerations

After production, biochar should ideally be activated before application. This can be done by mixing it with compost or soaking it in nutrient solutions. Such activation enhances its susceptibility to retain moisture and nutrients, maximizing its benefits when introduced to the soil.

6. Application of Biochar

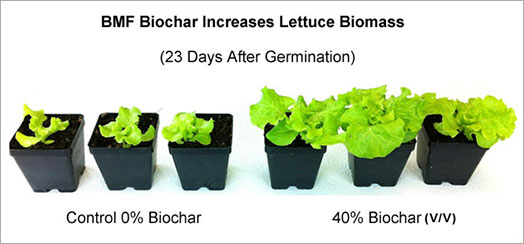

Biochar can be employed in various ways within agricultural practices. It can be mixed into the soil, used as a top dressing, or incorporated into potting mixes for various planting applications. The application rates may vary depending on the specific crops, soil types, and intended benefits—yet starting small and gradually increasing application rates is prudent.

7. The Environmental Impact

Beyond its agronomic advantages, small-scale biochar production holds substantial environmental implications. By recycling organic waste, it helps divert materials from landfills, thus reducing methane emissions. Additionally, biochar’s ability to sequester carbon significantly contributes to climate change mitigation strategies.

8. Conclusion

Small-scale biochar production represents a profound intersection of sustainability, innovation, and practical application. Its myriad advantages not only enhance soil health and agricultural productivity but also empower individuals and communities to foster ecological stewardship. As we delve deeper into the potential of cultivating our resources sustainably, biochar stands as a beacon for a greener, more resilient future. Thus, embarking on this journey not only benefits individual gardens and farms but serves a greater purpose in nurturing the Earth itself.