In the realm of waste management and energy production, the term “pyrolysis plant” has garnered increasing attention. But what exactly is a pyrolysis plant, and why is the process so captivating? This article explores the fundamentals of pyrolysis, delving into its mechanics, benefits, applications, and future prospects. It’s an intriguing intersection of chemistry, engineering, and environmental science, beckoning both scientists and laypersons alike.

What is Pyrolysis?

At its core, pyrolysis is a thermo-chemical decomposition of organic material through the application of heat in the absence of oxygen. This process causes complex organic materials, such as plastics, biomass, and tires, to break down into simpler molecular structures. The absence of oxygen is crucial; without it, combustion occurs rather than thermal decomposition, which is the defining characteristic of pyrolysis. The result? A plethora of valuable resources emerges from waste materials, paving the way to a more sustainable future.

The Pyrolysis Process: Step-by-Step

The pyrolysis process typically unfolds in several stages: feedstock preparation, heating, and product recovery. Let’s dissect each of these phases meticulously.

1. Feedstock Preparation

The initial step involves the careful selection and preparation of feedstock. Feedstock can encompass an array of organic materials: agricultural waste, plastic waste, rubber tires, and even municipal solid waste. Proper sorting and shredding are paramount; this ensures uniformity in size and composition, enhancing the effectiveness of the pyrolysis process.

2. Heating

Post-preparation, the feedstock enters a reactor where it undergoes heating. The temperature within the reactor can vary, typically ranging from 300 to 900 degrees Celsius, depending on the material being processed and the desired end products. Without oxygen, the materials slowly decompose, yielding three primary outputs: solids (char), liquids (pyrolysis oil), and gases (syngas). A fascinating aspect of pyrolysis is that these outputs have different applications, making the process highly versatile.

3. Product Recovery

Lastly, recovering and refining the products is crucial. The solid char can find utility as a fuel or a carbon-rich resource for agricultural use. Pyrolysis oil, a renewable alternative to fossil fuels, can be further refined and utilized in various industrial applications. Meanwhile, syngas—a mixture of hydrogen, methane, and carbon monoxide—can be combusted for energy or converted into chemicals and fuels. This multi-product capability hints at the potential to revolutionize how we approach waste.

Why Pyrolysis Plants Matter

It’s essential to grasp the multifaceted significance of pyrolysis plants. Traditional waste disposal methods, such as landfilling and incineration, present formidable challenges. Landfills consume valuable land and can lead to hazardous leachate; incineration, while useful, releases harmful pollutants into the atmosphere. Conversely, pyrolysis plants proffer numerous environmental benefits.

1. Waste Minimization

The ability to convert waste into valuable products significantly lessens the volume of material destined for landfills. By diverting waste streams away from landfills, pyrolysis not only helps mitigate environmental hazards but also capitalizes on resources that would otherwise be wasted.

2. Renewable Energy Generation

With the energy crisis looming large, pyrolysis offers a unique solution. The output products, notably pyrolysis oil and syngas, can be employed as renewable sources of energy. As the world shifts toward cleaner, more sustainable energy practices, these products represent a potential lifeline.

3. Carbon Footprint Reduction

Pyrolysis operates under a low-emission profile compared to conventional waste management methods. By converting waste into energy and raw materials instead of incinerating them, there is a notable reduction in greenhouse gas emissions. This is crucial in combating climate change.

Applications of Pyrolysis Products

As mentioned earlier, pyrolysis yields valuable outputs that can benefit various sectors:

1. Char

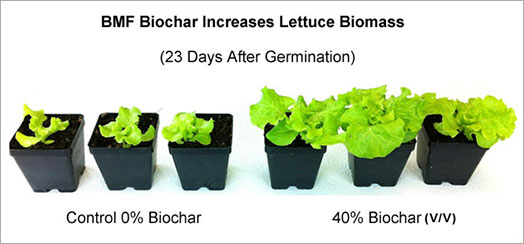

Often used as a carbon sequestration agent, char can improve soil health due to its properties of enhancing water retention and nutrient availability. Additionally, it finds application in the production of activated carbon, which is widely used in water purification and air filtration.

2. Pyrolysis Oil

This oil can be upgraded to produce transportation fuels comparable to diesel. Industries are progressively researching how pyrolysis oil can be integrated into existing fuel infrastructure, which could further catalyze the transition toward sustainable energy sources.

3. Syngas

This versatile gas can be used in power generation or as a precursor for the synthesis of hydrogen fuels. Additionally, syngas can serve as a building block for chemicals, presenting further opportunities for innovation.

The Future of Pyrolysis Plants

With the relentless pursuit of sustainability, the future of pyrolysis technology appears promising. Continuous research and development endeavors aim to enhance the efficiency of pyrolysis systems, as well as expand the range of feedstocks that can be processed. Moreover, integrating pyrolysis facilities with existing waste management and energy systems can create a synergistic ecosystem of resource recovery and energy production.

In conclusion, pyrolysis plants are more than mere industrial installations; they embody a transformative approach to waste management in our modern world. The intriguing process of turning waste into energy and useful chemicals holds the key to addressing some of the most pressing environmental challenges we face today. Indeed, the fascination with pyrolysis is not merely its scientific basis but the profound potential it holds for reshaping our future.